Wellplast Wins Double at Packnorth Award 2025

At this year’s Packnorth Award 2025, held during the Empack trade fair, Wellplast received two prestigious honors: Best Industrial Packaging 2025 and the event’s highest distinction, the Grand Prize 2025.

The awards were accepted on stage in front of a live audience at Empack and serve as a clear recognition of Wellplast’s innovative work in developing sustainable and efficient packaging solutions for industrial applications.

Wellplast extends its sincere thanks to AGIMEDIA, Packnews.com, and Empack for the nominations and the well-organized awards ceremony.

About the Award-Winning Product

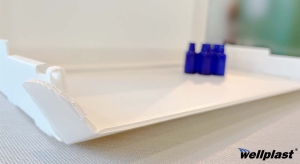

A stackable, resealable medical packaging tray in monomaterial – designed for sustainability, efficiency, and the packaging demands of tomorrow

Wellplast has developed a groundbreaking resealable tray optimized for automated workflows within the medical technology sector. This solution integrates functionality, hygiene, resource efficiency, and circularity into one packaging system.

Integrated Functionality and Design

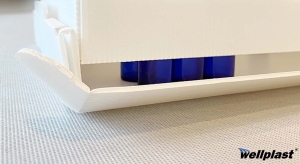

The tray consists of two parts – a lid and a base with resealable flaps – allowing for both stackability and easy access in automated environments. The side opening enables robotic systems to open and empty the tray without manual handling. The design has proven so effective that one customer has modified their production line specifically to accommodate this packaging.

Meeting Medical Cleanliness Standards

The material used in the tray meets strict cleanliness requirements and is developed for use in controlled environments. It does not release dust or fibers and is approved for direct contact with both medical devices and food. The tray supports various sterilization methods including ETO, autoclaving, and irradiation. Its moisture-resistant, air-insulated structure also makes it suitable for chilled and frozen products. By packaging directly in clean zones – or even at the supplier level – it reduces the need for repackaging, washing, or sanitizing reusable containers.

Monomaterial for Circular Recycling

The tray is made entirely of polypropylene (PP) – a material known for its strength, chemical resistance, and moisture tolerance. Using a single material ensures easy and efficient recycling, in line with EU directives on reuse and recyclability. No disassembly is needed – the entire tray can be sorted as plastic and recycled within existing systems.

No Additives – Safer for Health and Environment

The inherent properties of the material eliminate the need for coatings, dyes, or additives – avoiding potentially harmful substances while meeting high standards for food safety and medical hygiene. Its white appearance meets cleanliness requirements without compromising recyclability.

Lightweight, Durable, and Resource-Efficient

The tray is lightweight yet robust, reducing material use and environmental impact from transport. Its durability allows it to function as both a single-use and reusable solution, supporting resource efficiency without sacrificing performance.

Designed for Transport Optimization

To further reduce emissions and transport costs, the trays are delivered flat, significantly minimizing shipping volume and reducing the number of required transport cycles.

Responsible Manufacturing with Certified Quality

Production takes place in Sweden in an ISO 9001 and ISO 14001 certified facility, upholding high standards for quality, environmental management, and workplace safety. Local manufacturing ensures traceability, short transport distances, and strong ethical and social conditions throughout the supply chain.

Aligned with Market Demands

With its pure material composition, certified local production, and clear recyclability, the tray meets the growing market demand for sustainable, certifiable packaging. Where needed, full material traceability – such as certified raw material sourcing – can be easily documented.